TENSOLOGY Technicians are factory trained and experienced in carrying out Magnetic Rope Testing (MRT) on wire ropes across all industry sectors.

Many ropes deteriorate from the inside which is a worry to the rope examiner as the traditional inspection technique of visual examination is not adequate. Multi-strand, rotation resistant ropes are particularly susceptible to internal degradation because of the way the ropes are constructed.

Alternate layers of right hand and left hand lay strands causes numerous point contacts along the entire length of rope. These point contacts see high stresses when the rope is loaded causing localised deformation and wear. Repeated bending under load adds to the problem as fatigue cracks form at the contact points, eventually causing the wires to break. This internal degradation is the primary cause of unexpected wire rope failure and as a result, all safety critical industries recognise the need for MRT in assessing the condition of ropes. The consequences of a rope failure include death or injury to personnel, damage to equipment and reputation, legal claims and loss of revenue. The cost of carrying MRT is more than offset by the cost of failure and the cost of premature discard.

In order to best satisfy the LEGAL REQUIREMENTS for inspecting and examining ropes, the relevant standards, specifications and guidance documents should be followed. Documents covering the inspection, examination and assessment of wire ropes across the various industry sectors include:

ISO 4309:2017 "Cranes - Wire ropes - Care and maintenance, inspection and discard".

EN 12927:2019 "Safety requirements for cableway installations designed to carry persons".

IMCA LR 004, IMCA HSSE 023, IMCA M 197 Rev.1 - October 2018 "Guidance on Examination of Steel Wire Rope Through MRT".

MRT is an integral part of these standards and the information gained from the MRT test is a major factor in deciding whether a rope is safe to remain in service. It is a requirement that MRT tests are only carried out by properly QUALIFIED people using CERTIFIED equipment.

Visual inspection is not pracitical or effective in some circumstances. Both internal and external inspection of long lengths of rope that are heavily lubricated is only possible by utilising MRT.

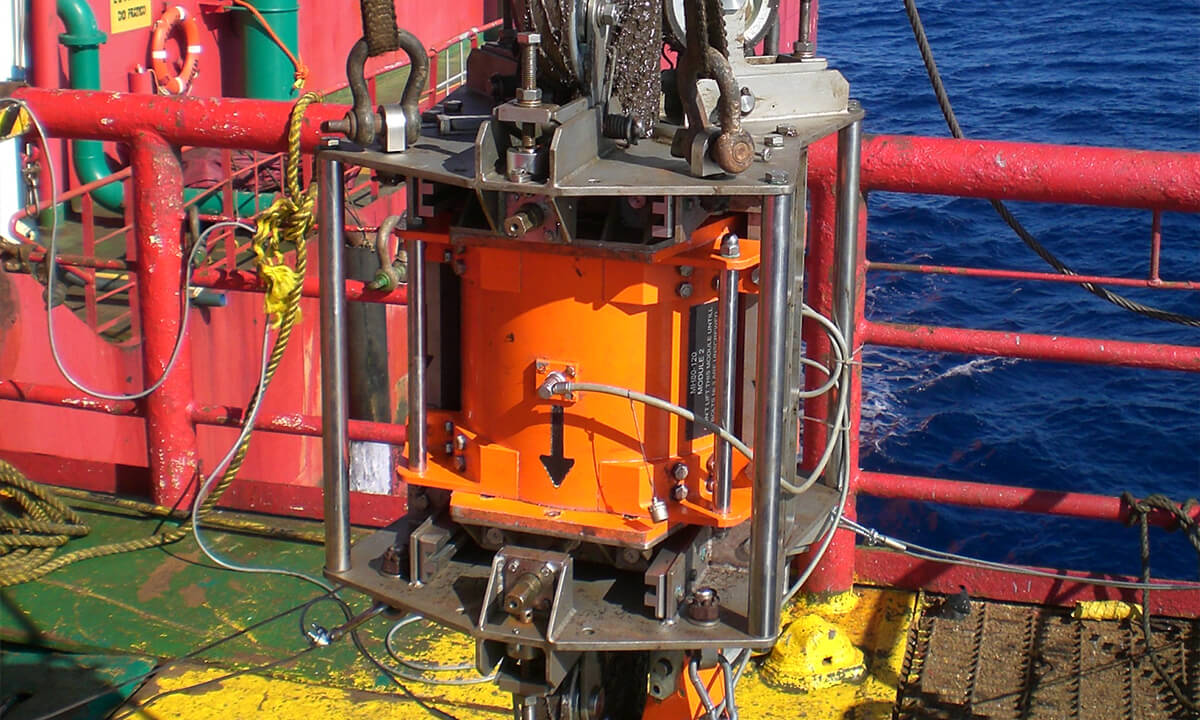

MRT of large diameter offshore lifting rope

MRT of large diameter offshore lifting rope

There is a LEGAL requirement to periodically, thoroughly examine wire ropes used for lifting to ensure their continued safe use. For certain ropes, this task is made more difficult because of their construction and the local environment in which they are used. For example, in order to thoroughly examine a multi-strand rope used for offshore heavy lifting, it would not be possible to check for internal degradation caused by interwire contact or corrosion whilst the rope is in service without MRT. It would also not be practical to visually check the full circumference of the rope along its entire length due to operator fatigue and the fact that the surface of the rope is covered in a thick lubricant.

Periodic thorough examination is only possible by carrying out MRT.